Need help? Call us:

+91-8978599976

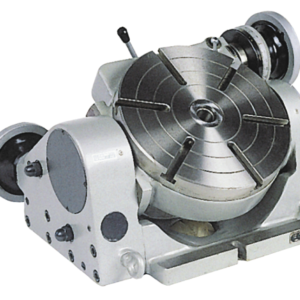

Horizontal / Vertical Rotary Table with Chuck

Model No. HV-4, HV-6, HV-8, HV-10, HV-12, HV-14, HV-16

Quote Request & Pricing

Shipping calculated at checkout.

Have any Questions?

Feel free to Get in touch

🔥 Buy More Save More!

A horizontal/vertical rotary table is a precision work positioning device used in metalworking. It is an extremely useful accessory for a milling machine. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. It can be used for milling curved profiles and angled faces relative to a centre line. When mounted vertically with a tailstock, it can be used to machine shafts or spindles.

Main Features:

- Table made of high density Meehanite inspect angle to assure the excellent quality and durableness

- Use excellent machining center to process. Spindle end be applied accuracy bearing. Cab be assured to keep very steady under load cutting.

- Worm is hardened and ground. The ratio is 90:1. The work table is graduated a full 360 deg so that one turn of the handle moves the table through 4 deg. Micro collar is graduated in steps of 1′ min and vernier scale makes settings down to 10 seconds possible.

- They are widely used for circular cutting work, angle setting, boring, spot-facing and similar work.

- Indexing accuracy of direct indexing mechanism. Maximum cumulative spacing error 1 min.

- Please choose Front-Lock 3-Jaw chuck only.

Standard Accessories: Flange, Tailstock, Dividing Head

Dividing Head Dp-1: HV-4, HV-6; Dp-2: HV-8; DP-3: HV-10, 12, 14, 16

Tail Stock TS-1: HV-4, HV-6; TS-3: HV-10, 12; TS-4: HV-14

Flange FLT-103 & 103A: HV-4; FLT-104 & 104A : HV-6; FLT-0 & 0A: HV-6, 8; FLT-1 & 1A: HV-8, 10; FLT-2 & 2A: HV-10, 12, 14; FLT-3 & 3A: HV-10, 12, 14, 16

| Model No. | HV-4 | HV-6 | HV-8 | HV-10 | HV-12 | HV-14 | HV-16 |

|---|---|---|---|---|---|---|---|

| Description | HV Rotary Table | HV Rotary Table | HV Rotary Table | HV Rotary Table | HV Rotary Table | HV Rotary Table | HV Rotary Table |

| Optional Accessories | VSC-3A | VSC-5A | VSC-6A | VSC-7A, 8A | VSC-7A, 8A | VSC-7A, 8A | VSC-10A |

| Center Sleeve | MT-2 | MT-2 | MT-3 | MT-3 | MT-4 | MT-4 | MT-4 |

| Table Outer Dia D | 110 mm | 150 mm | 205 mm | 254 mm | 305 mm | 353 mm | 406 mm |

| Table Height H | 72 mm | 80 mm | 102 mm | 109 mm | 125 mm | 125 mm | 130 mm |

| Deg Per One Handle Rotation | 4 Deg | 4 Deg | 4 Deg | 4 Deg | 4 Deg | 4 Deg | 4 Deg |

| Scale of Micro Collar | 2' | 2' | 1' | 1' | 1' | 1' | 1' |

| Vernier Reading | 20" | 20" | 10" | 10" | 10" | 10" | 10" |

| Gear Ratio | 1:90 | 1:90 | 1:90 | 1:90 | 1:90 | 1:90 | 1:90 |

| Load Capacity-Horizontal | 35 Kg | 40 Kg | 80 Kg | 90 Kg | 120 Kg | 130 Kg | 140 Kg |

| Load Capacity-Vertical | 18 Kg | 20 Kg | 40 Kg | 50 Kg | 60 Kg | 70 Kg | 70 Kg |

| Bolt Slot - g | 17 mm | 17 mm | 17 mm | 18 mm | 18 mm | 18 mm | |

| Width of T-Slot -e | 11 mm | 11 mm | 14 mm | 14 mm | 16 mm | 16 mm | 16 mm |

| Model No. HV Rotary Table | HV-4, HV-6, HV-8, HV-10, HV-12, HV-14, HV-16 |

|---|---|

| 3-Jaw Self-Centering Chuck | VSC-3A, VSC-5A, VSC-6A, VSC-7A, VSC-8A, VSC-10A |

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.